Orange Dodecahedrons with Green Leaves

It’s pumpkin season and these little chainmaille fidget toys are ready to roll! Each “pumpkin” is actually a dodecahedron (12-sided figure). They’re fun to make and add a touch of geeky charm to your Halloween or Thanksgiving decor.

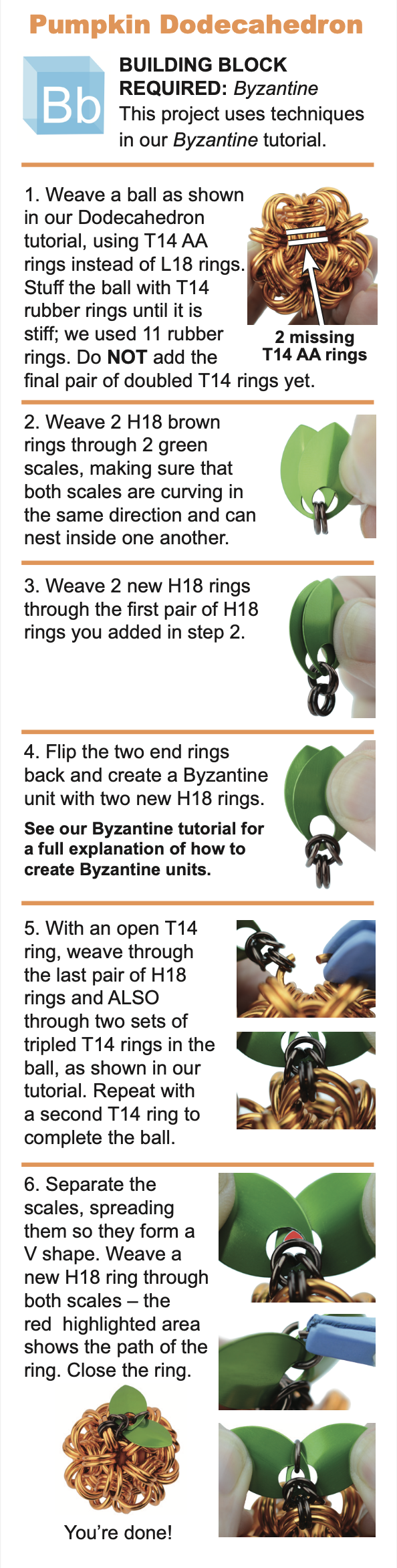

The pumpkins follow the basic Dodecahedron pattern, and have extra jump rings added as stuffing to give the pumpkins a plump shape. Adding the leaves as shown requires some Byzantine basics, but even if you don’t know Box/Byzantine, you may be able to figure it out with the diagram below. Or, you can skip the leaves and just add a few brown rings for a stem.

We don’t currently offer orange kits, but we do have other chainmaille dodecahedron kits in the B3 Etsy shop. Within that listing, feel free to click on the “contact seller” button to special request any color combination you’d like. (We’re working on adding more custom kit options for automatic ordering soon.)

🐈 Tips for Cat Owners:

These pumpkins are irresistible to curious paws! Be sure to supervise your feline friends when they’re in the vicinity of the dodecs. (I may be speaking from experience here…)

Here are four size options for dodecahedrons in common jump ring sizes. The P16 size is the “squishiest” and requires more stuffing rings to hold its shape. The T14 pumpkin uses small size scales, and all the other pumpkins are shown with itty bitty/micro green scales and size D20 connector rings. D20 = 20 awg (0.8mm) 1/8″ (3.2mm)